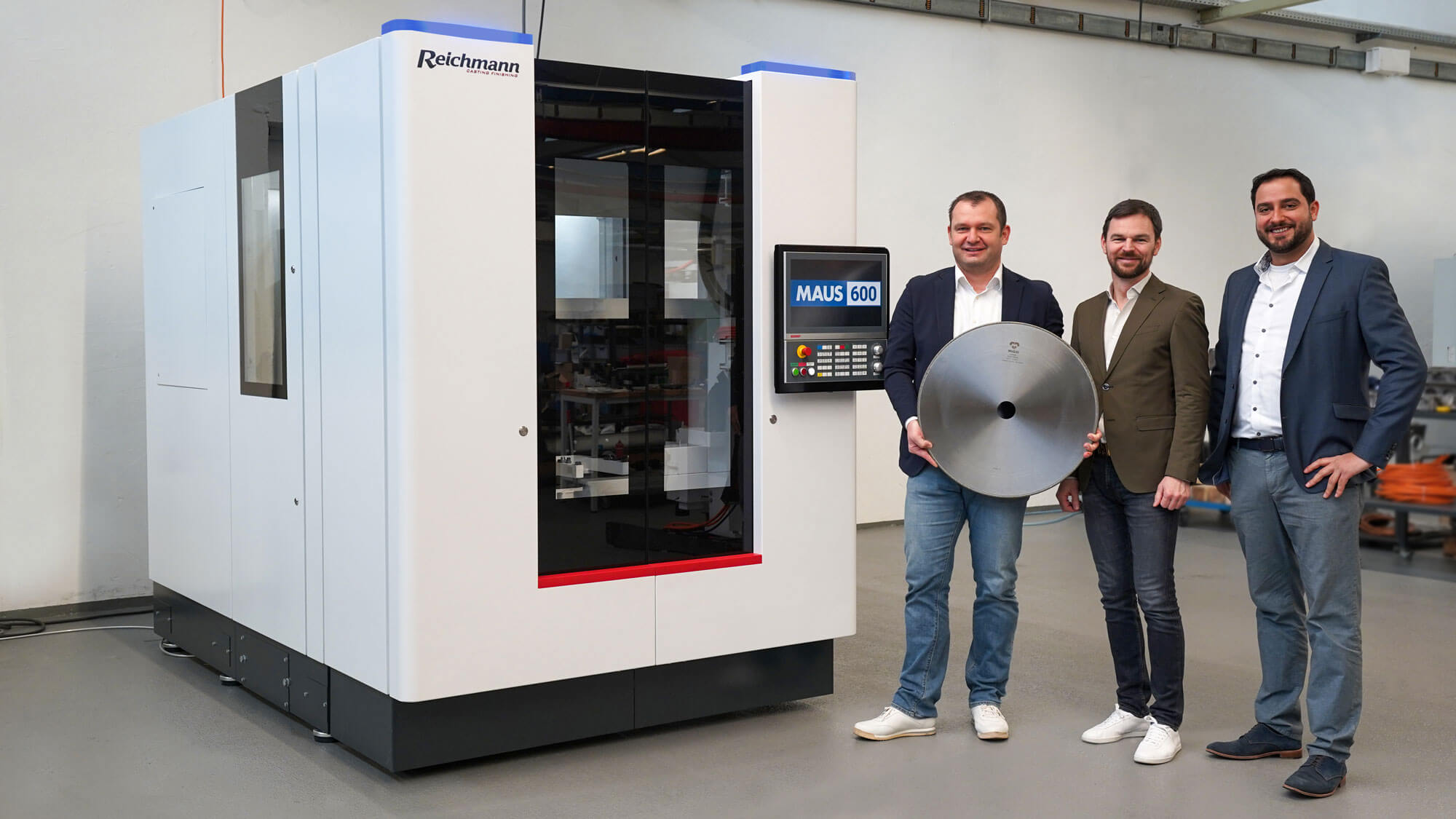

Reichmann and c-Parts announce cooperation: Initial equipment of the new MAUS line with Muzzi grinding wheels

All machines of the new MAUS series are equipped with the tried-and-tested diamond tools and optionally with the newly developed changing system for contour and inner grinding from the well-known Muzzi brand. The cooperation between Reichmann and the grinding wheel sales partner c-parts rounds off the equipment of the new MAUS casting finishing centre to form a coherent overall package that sets new standards on the market.

With the new MAUS Line, Reichmann is presenting a new generation of automatic grinding systems that focus on maximum user benefit with an innovative control system for the simplest operation and a well-thought-out machine design.

Four different machine versions, starting with the MAUS 600 (for castings up to 600 mm in diameter and weighing 100 kg), through the MAUS 900, 1400 and 2200, process castings with a maximum diameter of 2,200 mm and a weight of up to 1,000 kg with two or three tools or optionally a tool changer in a compact housing.

The new generation of automatic grinding machines "Made in Germany”

The heart of the new fettling machines is the innovative control system. Programming with the Windows 10-based control is so intuitive that even users without prior knowledge can create new machining programs in no time. With the help of the pre-installed function favourites, setup is child's play. This solves staff problems and ensures high user acceptance. The standardized fixture interface also saves time when setting up new cast parts. This means that the automatic fettling centre is efficient and economical even for the smallest batch sizes and can be used flexibly for different castings. Numerous other equipment elements, such as an intelligent laser measuring system, a pallet changer or a new chip concept, ensure maximum process reliability, time savings and user-friendliness.

Cooperation with grinding wheel supplier c-parts GmbH

With the grinding wheel supplier c-parts from Mengen, Reichmann has found the right partner for the initial equipment of the new MAUS line. The high-quality Muzzi diamond grinding wheels impress with their long service life and precise results. The new optional Muzzi changing system offers even more flexible processing with low tool costs. With the practical plug-in system, the tool can be quickly and easily adapted to the conditions of the workpiece. This ensures optimized processing results.

The company c-parts from Mengen is responsible for the distribution of Muzzi products in Germany. Muzzi is a leading Italian manufacturer of diamond tools and grinding wheels for foundries and the mechanical industry. The many years of experience, flexibility and the high-quality standards of c-parts and Muzzi fit perfectly with the orientation of Reichmann and the new Maus product line. "Through the cooperation with c-parts and Muzzi, we like to offer our customers a convincing overall package. Together we are setting new standards in automatic casting finishing,” says Stefan Reichmann, Managing Director of Reichmann & Sohn GmbH.

Reichmann Casting Finishing - Innovative solutions for automatic grinding

In 2021, Reichmann & Sohn GmbH acquired the intellectual property of the Italian mechanical engineering company MAUS s.r.l. This way, Reichmann aims to further expand its leading position in automatic casting finishing and combine the competencies of Reichmann and Maus in new, innovative machine concepts.